2024 Highlights: Advancing Manufacturing Excellence at RPWORLD

1

12024 Highlights

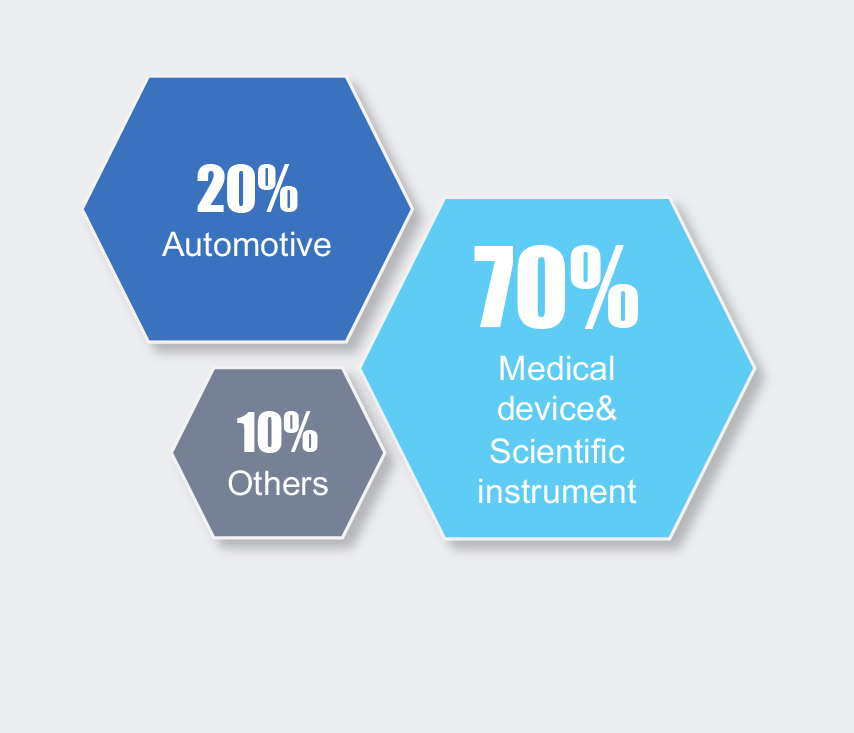

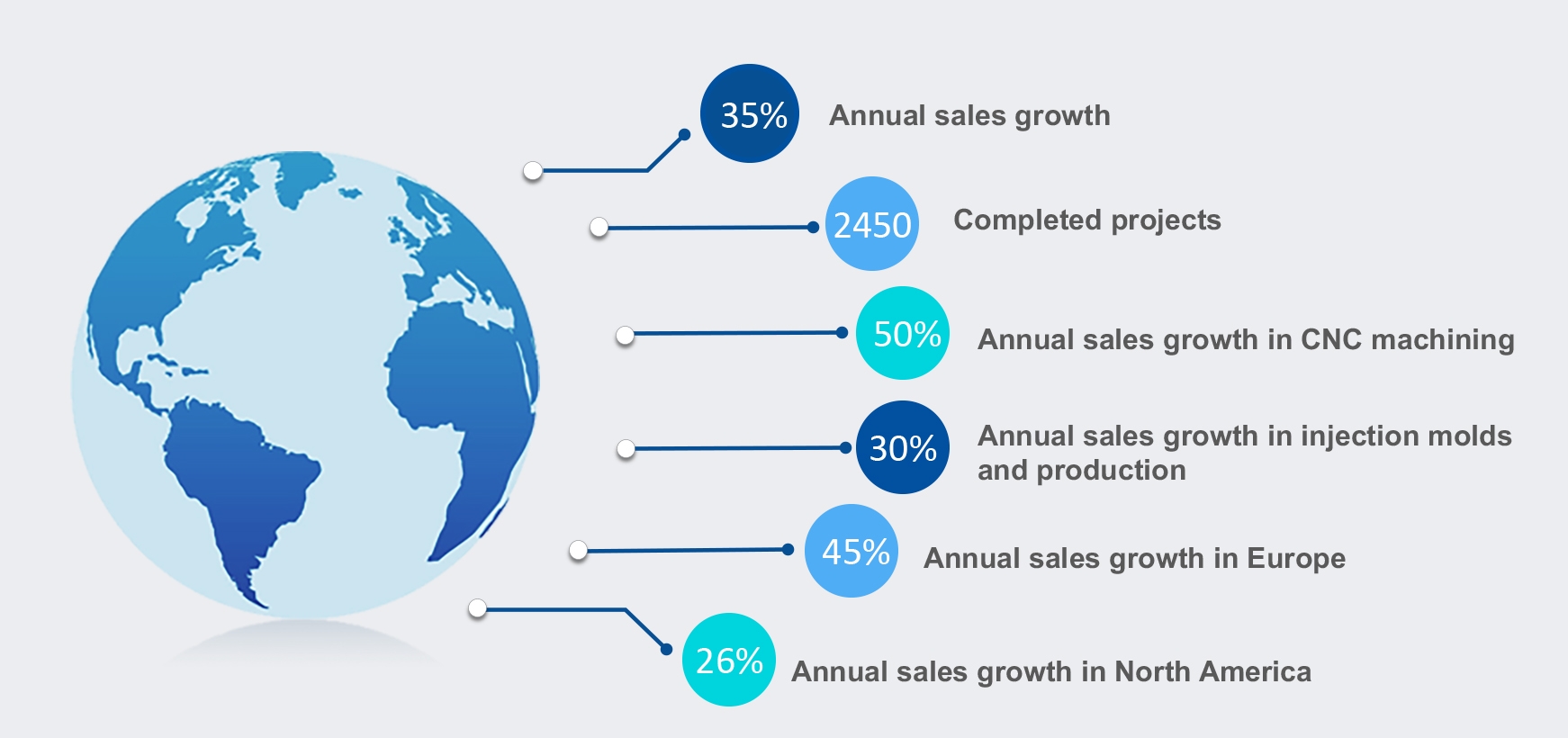

From medical and scientific instruments to automotive and beyond, our commitment to quality and speed has driven remarkable achievements in 2024. The following highlights demonstrate the impact of our tailored services and expanding capabilities.

2

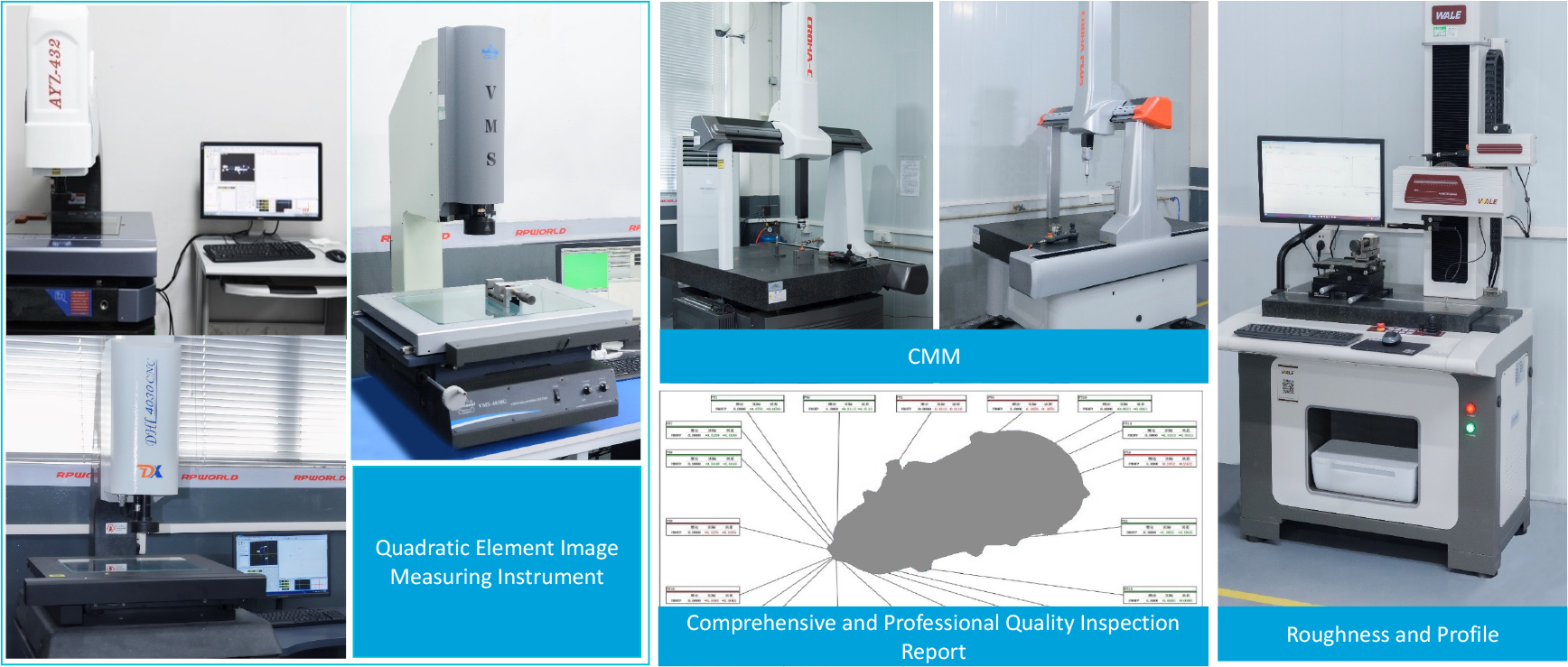

2Elevating Quality Standards with Certifications and Advanced Inspection

- ● Our certifications, including ISO9001, ISO14001, and ISO13485, reflect our commitment to maintaining the highest quality and environmental standards.

- ● On-site CNC inspection to integrate production and quality control seamlessly.

- ● Adding more advanced inspection machines, including Coordinate Measuring Machines (CMM), 3D image measuring machines for dimensional checks, and more measuring machines. These initiatives have significantly improved inspection efficiency, helping to shorten lead times and deliver parts faster to our customers.

3

3Increased CNC Production Efficiency by 50%

Our CNC operations have undergone significant upgrades to deliver unparalleled efficiency. These upgrades have resulted in a 50% capacity increase, allowing us to meet diverse customer demands more effectively.

- ● We have optimized our CNC operations by establishing dedicated facilities for prototyping and mass production, ensuring greater efficiency and focus for each process.

- ● Enhanced 5-axis capabilities with nearly 50% of 5-axis CNC machines, alongside the addition of turning equipment and other standardized equipment.

4

4Injection Molding Capacity Growth by 30%

- ● Comprehensive tooling solutions such as rapid tooling, soft tooling, and hard tooling, as well as specialized options like insert and over-molding.

- ● Enhanced post-processing capabilities, including painting, silk printing, pad printing, digital printing, water plating, NCVM, laser etching and more.

- ● Added value with mold flow analysis for optimized tooling design.

5

5Expanded Supply Chain and Process Offerings

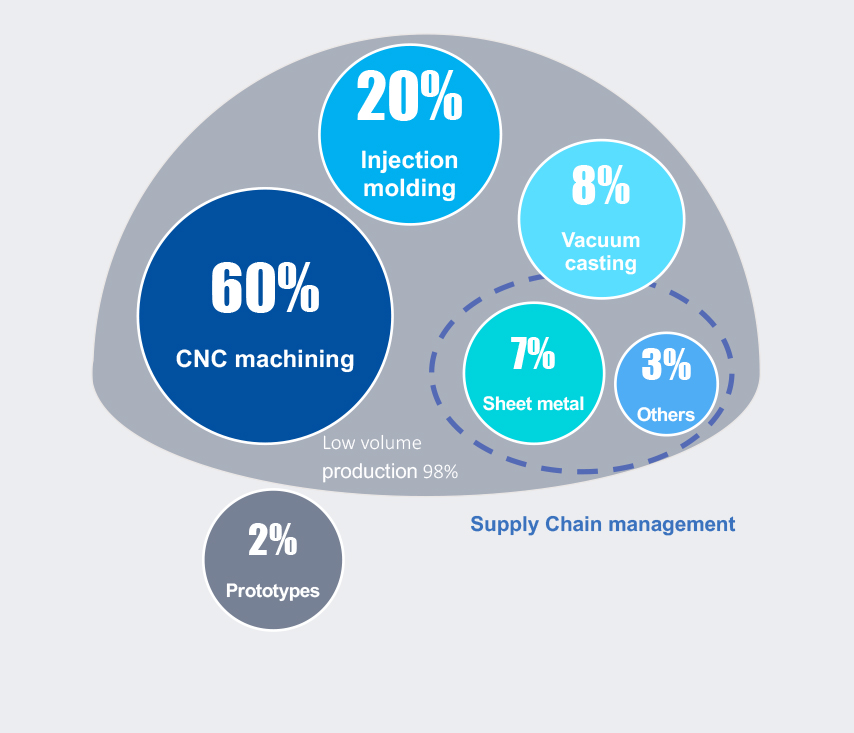

With the addition of sheet metal fabrication and die casting processes, we've enriched our process portfolio to serve a wider range of production requirements. These additions position us as a one-stop manufacturing provider, capable of providing comprehensive manufacturing services under one roof.

6

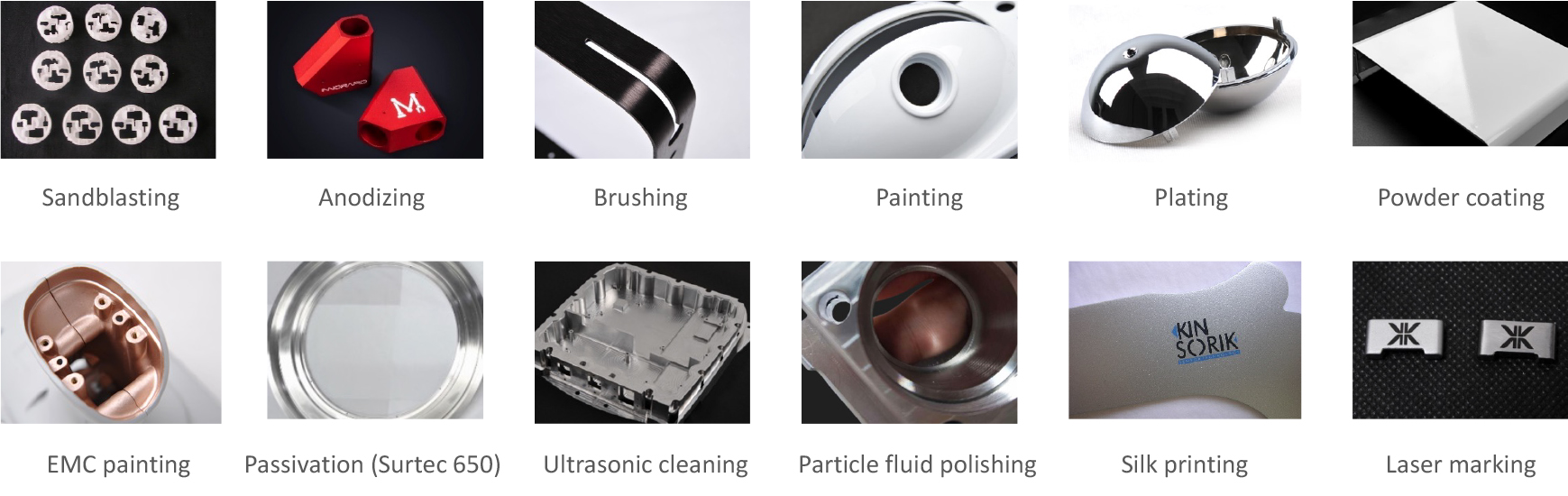

6Diversified Surface Treatments

- ● New anodizing factory was founded to further expand in-house finishing capabilities and better control the quality.

- ● Introduction of advanced processes like passivation, ultrasonic cleaning, magnetic polishing, and particle fluid polishing.

- ● Separation of dust-free and standard finishing workshops for greater operational flexibility.

7

7Strategic Development & Driving Customer Benefit

8

8Customer-orientated Services

9

9A Vision for 2025: Empowering Customers Through Enhancements

As we look forward to 2025, our focus remains on supporting our customers with customized manufacturing solutions that deliver faster production times, enhanced quality, and a seamless transition from prototyping to full-scale production—accelerating your product to market.

From our one-stop manufacturing services to the adoption of new machines and capacity expansions, every step we take is guided by our commitment to meeting your unique needs. Additionally, we aim to strengthen our contributions to environmental sustainability and social responsibility through enhanced sustainability initiatives.

Let's work together to make 2025 a year of innovation, growth, and collaboration!

INQUIRY

MOST POPULAR

- Congratulations to INNORAPID LIMITED for Obtaining "High-tech Enterprises Certification"!

- Know the Content of Materials, Get Better Products!

- The 6th Anniversary Gala of Changsha Office, RPWORLD

- Analysis of UL Flammability Standards I

- Inspect Faster & More Accurately—RPWORLD Upgraded Inspection Capability Again

- Sustainable Manufacturing at RPWORLD

15 January, 2025

15 January, 2025