Slash Your CNC Part Costs

— 4 Smart Design Tips to Minimize Setups

For product designers aiming to lower costs and boost efficiency, selecting the

right CNC design strategies is a game-changer. One critical yet often overlooked factor is the

number of setups required during machining. The design and alignment of setups significantly impact

production costs and part precision. This article explores effective design tips for reducing

setups, providing actionable insights for mechanical product design engineers.

Why Reduce the Number of Setups?

Each time a part is secured in a fixture and aligned for machining, it’s

called a “setup”. Setup operations are essential for achieving precision but come at the

cost of additional time, labor, and potential errors. From a design perspective, reducing setups

eliminates redundant processes, lowers costs, and enhances machining precision and consistency.

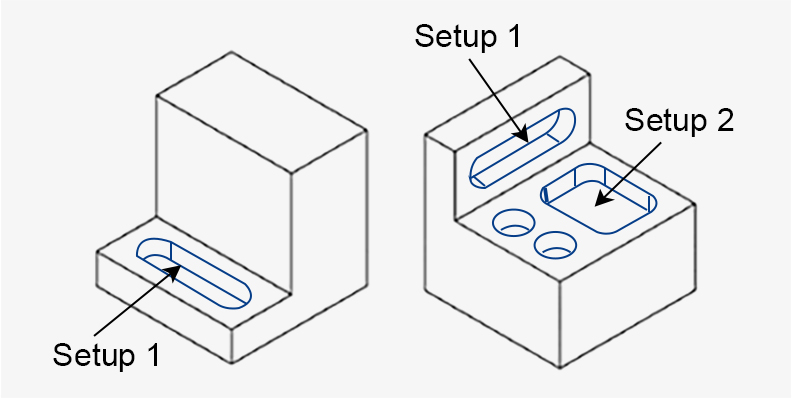

Impact on Costs

Minimizing setups directly reduces machining time and associated expenses. For

instance, a part requiring machining on both sides with blind holes typically needs at least two

setups: one for each side. Each reorientation or repositioning adds manufacturing costs and, for

complex parts, might need custom fixtures, further increasing expenses.

Figure-1

Impact on Precision

To achieve maximum positional accuracy between two or more

features, machining them in a single setup is essential. Each new setup might bring minor but

cumulative errors, regardless of fixture precision, which can compromise the part’s overall

accuracy.

Design Strategies to Reduce Setups

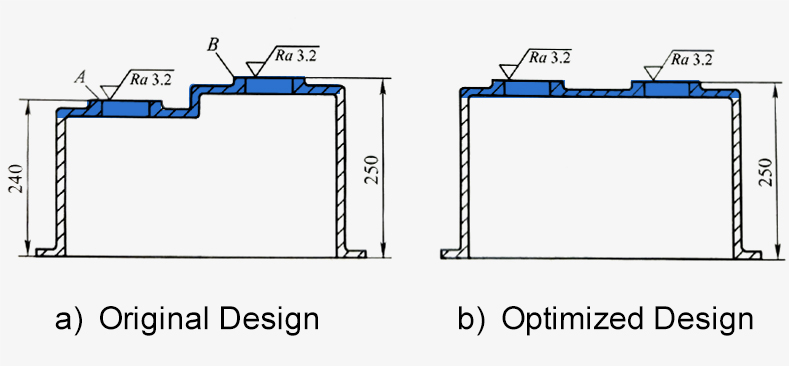

1. Align Machining Surfaces to the Same

Height

Inconsistent surface heights often require multiple

adjustments to the machine. For example, if features A and B are at different heights, machining

them in a single setup becomes challenging. By aligning these surfaces to the same height in the

part design, both features can be machined simultaneously, eliminating unnecessary adjustments and

reducing part costs.

Figure-2 Align machining surfaces to the same

height to allow for a single setup.

height to allow for a single setup.

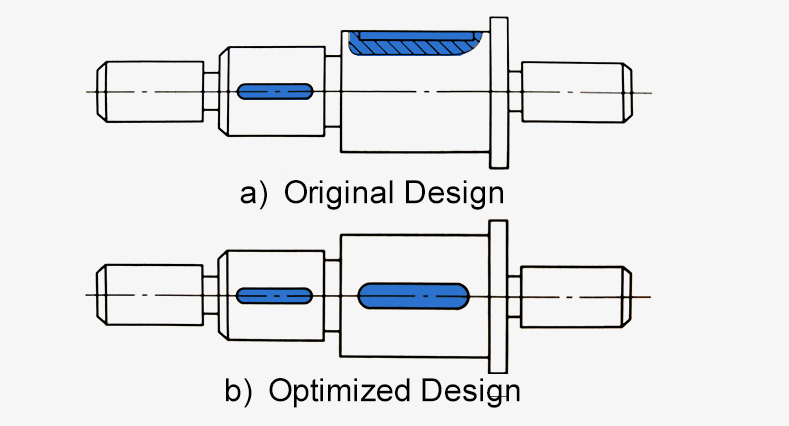

Figure-3 Standardize keyway directions to

enable machining in a single setup.

enable machining in a single setup.

2. Standardize Keyway Directions

When keyways on a shaft are not aligned in the same

direction, multiple setups and realignments are required for milling. By ensuring keyways are

oriented consistently, machining can be completed in fewer setups, reducing costs and improving

positional accuracy.

3. Break Down Complex Structures into Simpler

Components

Highly intricate parts often require multi-axis CNC machines,

which come with higher hourly rates. Instead, consider breaking down complex structures into simpler

components that can be machined separately and then assembled through threading, welding, or other

post-processing techniques. This approach not only reduces costs but also improves the relative

positional accuracy of features.

This rapid turnaround can be extremely beneficial for industries like automotive and consumer electronics, where staying ahead of trends can make or break a product’s success. The ability to quickly iterate and refine designs ensures companies remain at the forefront of their markets.

This rapid turnaround can be extremely beneficial for industries like automotive and consumer electronics, where staying ahead of trends can make or break a product’s success. The ability to quickly iterate and refine designs ensures companies remain at the forefront of their markets.

4. Avoid Multiple Surface Treatments

Surface treatments enhance the appearance and durability of

CNC parts but add to production costs, particularly when multiple treatments are required. Machining

paths are one of the primary design constraints in milling. To access all surfaces of a model, the

workpiece often needs to be rotated or flipped multiple times, further increasing expenses. To

minimize costs, either avoid surface treatments altogether or reduce the number of treatments

required.

Figure-4

Avoid multiple surface treatments

to reduce setup times.

Avoid multiple surface treatments

to reduce setup times.

Key Takeaways for Design Engineers

By implementing these design strategies, mechanical product design

engineers can bridge the gap between innovative design and efficient production, ensuring a seamless

journey from concept to creation. Explore how RPWORLD expertise in CNC machining can bring your

designs to life. Contact us today.