The client asked for a design with no screws, so clips are chosen. However, the clip hook was broken during drop testing, what should we do?

---An engineer

|

1. Commonly used clip shapes |

|

2. Factors to be considered before clips are designed |

● Mechanical properties of the plastic material

● Number of times to be assembled or disassembled

● Stress and strain that the clip to be withstand

during assembly

● Mechanical pressure applied to the clip after assembly

1. Reasonable lengths

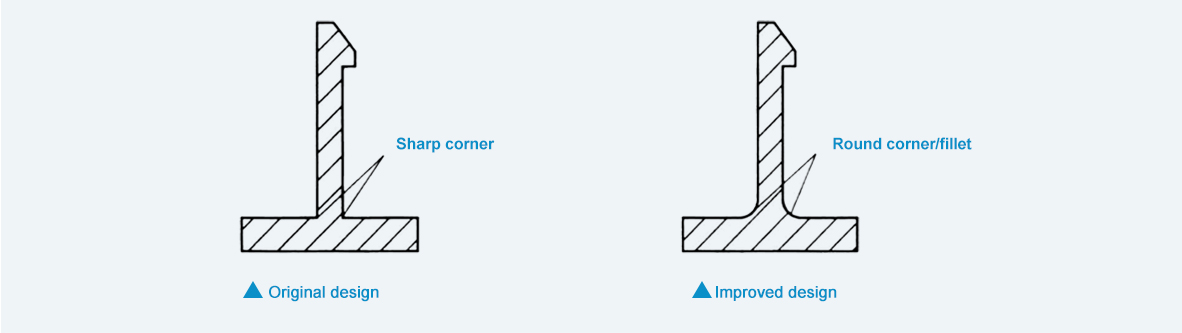

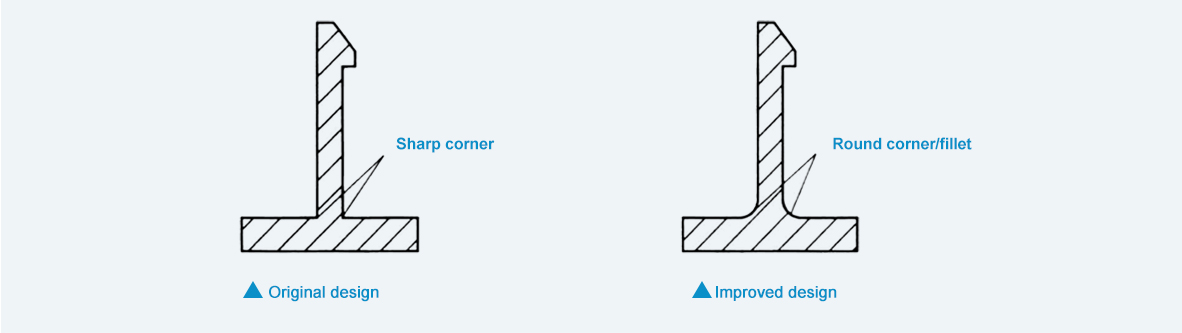

2. To avoid stress concentration by adding round corners or fillets at the base of the clips

3. Clips shall be evenly distributed

4. Use positioning columns to assist the clip assembly

5. Well-designed clips should not increase mold complexity

6. Well-designed clips shall be easy for mold modificationTags: Prototype CNC machining Injection Molding Urethane Molding 5 Design Tips to Cut the Cost